Long bar induction heat treatment machine

Features:

Application: Quenching & Tempering

Material Heated:45#,40Cr,42CrMo,65Mn

Diameter range: ø10-120mm

Heating way: Induction heating

Product Detail

Application Video

Product Tags

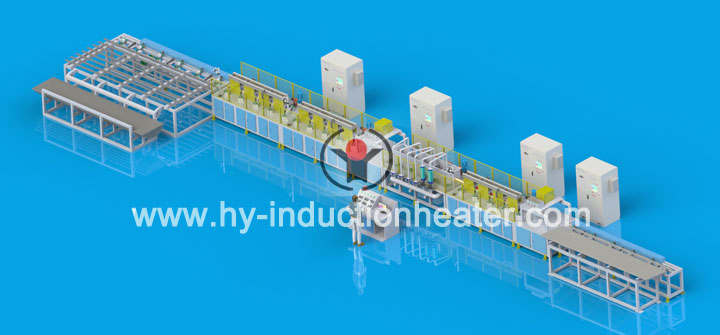

Long bar induction heat treatment line

● Product name:Long bar induction heat treatment line, round bar quenching tempering line

● Diameter range: ø10-120mm

● Length range: Not limited, especially suitable for long bars/rod

● Product strength: Uniform heating, uniform quenching, good heat treatment effect

● Control way: Siemens PLC

We are the only manufacturer which has the ability to manufacture intelligent mediate frequency power supply in China. When exchanging different size of inductors, the user need not do any adjustment for power supply parameters.The power supply can adapt to the load resonant frequency, which is one of the important factors to ensure the performance of pipe after quenching & tempering can reach requirements.

Main configuration for Long bar induction heat treatment line

● Energy saving IF power supply

● Storage platform

● Transportation roller system

● Induction heater for quenching

● Spray cooling system

● Induction heater for tempering

● Cooling platform

● Enclosed closed cooling machine

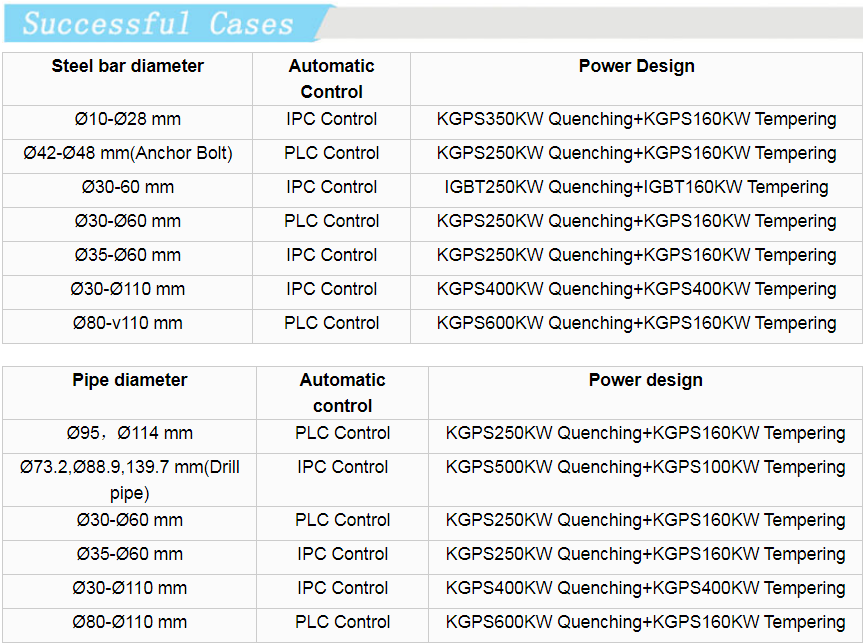

At present, our factory has 70 staffs, including 6 professional engineers and 10 technicians. The complete production line design and production will be all finished in our factory.Here we are listing our typical cases for your reference.

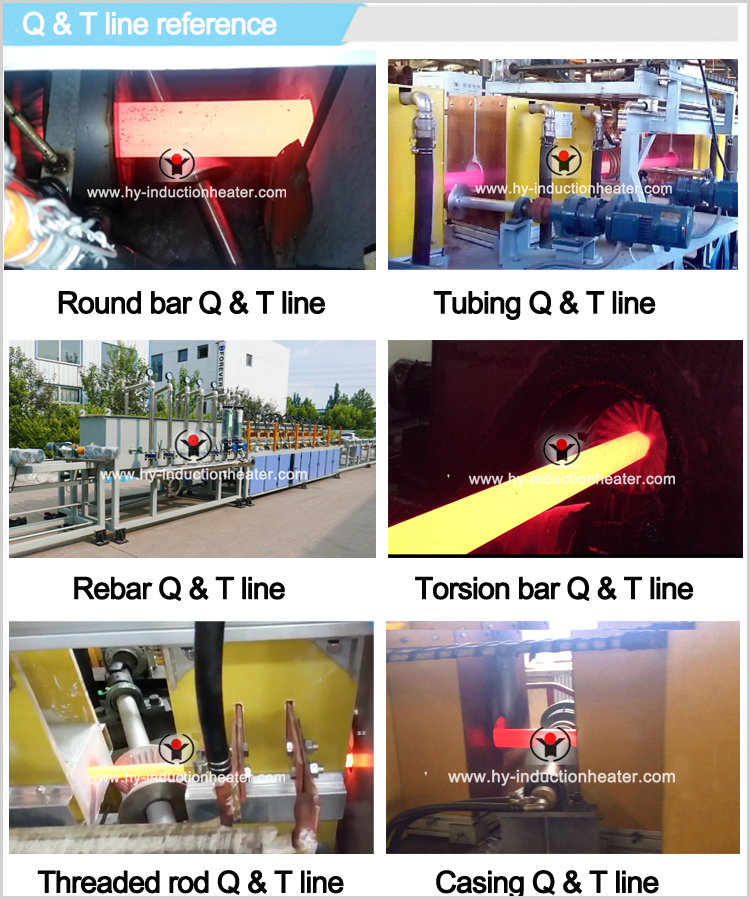

● In 2008, Designing & manufacturing the first grinding rod quenching & tempering production line for mining industry in China;

● In 2009, Designing & manufacturing the first 2500KW steel bars induction heating production line for hot rolling steel balls.in China;

● In 2012, Designing & manufacturing the first 4000KW induction heating line working with IF power supply and superaudio frequency for rebar hot rolling in China.(This is for China Kun gang steel group,which is state-owned enterprise);

● In 2013, Designing & manufacturing 7500KW induction heating production line for billet online continuous casting and rolling;

● In 2015,Designing & manufacturing the first fully automatic drill pipe surface quenching production line for oil industry in China;

● In 2015, Designing & manufacturing ø73.02-139.70mm casing quenching & tempering production line for Philippines customer

● In 2016, Designing & manufacturing the first 2800KW steel bars induction heating production line used for hot rolling steel balls, parallel preheating and series heating. The power consumption is 260kwh per ton.

● From 2009 to 2016, Designing & manufacturing a number of wind power anchor bolt quenching & tempering line,the quantity and quality ranked first in China.

If you are interested in our induction heating equipment, please send us inquiry at

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.